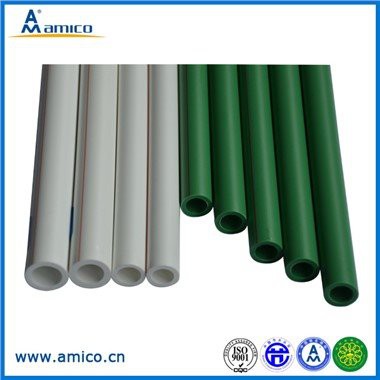

Anti-bacterial PPR Pipe

Ningbo Amico Plastic Industry Inc. located in Ningbo China, is a stock-holding enterprise, which specialized in producing pipes and fittings. With annual productivity over 10000 tons, Ningbo Amico Plastic Industry Inc. mainly produce plastic aluminum pipe, PP-R pipe, PE-RT pipe, HDPE pipe, PE-RT heating pipe series, brass adapter etc. Amico been awarded the title of Name-brand frequently and acquired ISO9001 and ISO14001 certificate. As early as 2004, Amico plastic aluminum pipe and PP-R pipe were titled as "Chinese best seller brand" Amico pipes and fittings enjoy high praise from home and abroad. So far, the company domestic sale network spreads more than 20 provinces. Meanwhile, the products are popular in various countries, such as Russia, the Phillipines, Chile, Indonesia etc.

Company Profile

Ningbo Amico Plastic Industry Inc. located in Ningbo China, is a stock-holding enterprise, which specialized in producing pipes and fittings. With annual productivity over 10000 tons, Ningbo Amico Plastic Industry Inc. mainly produce plastic aluminum pipe, PP-R pipe, PE-RT pipe, HDPE pipe, PE-RT heating pipe series, brass adapter etc. Amico been awarded the title of Name-brand frequently and acquired ISO9001 and ISO14001 certificate. As early as 2004, Amico plastic aluminum pipe and PP-R pipe were titled as "Chinese best seller brand" Amico pipes and fittings enjoy high praise from home and abroad. So far, the company domestic sale network spreads more than 20 provinces. Meanwhile, the products are popular in various countries, such as Russia, the Phillipines, Chile, Indonesia etc.

Why choose us

High quality

Our products are manufactured or executed to very high standards, using the finest materials and manufacturing processes.

Professional team

Our professional team collaborate and communicate effectively with one another, and are committed to delivering high-quality results. They are capable of handling complex challenges and projects that require their specialized expertise and experience.

Long warranty

The long-term warranty is designed to give consumers more confidence that their purchases and services will continue to be valid.

Rich experience

Dedicated to strict quality control and attentive customer service, our experienced staff is always available to discuss your requirements and ensure complete customer satisfaction.

What is Anti-Bacterial PPR Pipe

Anti-Bacterial PPR Pipe is a kind of PPR pipe with laminar dense structure. Its inner antimicrobial layer is made of high crystalline nanometer level active material, which can release Ag ions to kill bacteria, while the outer layer is made of food-grade PPR raw material, which is non-toxic, safe, and has the function of light blocking. The pipe is opaque after special process, not easy to breed bacteria and can prevent microbial photosynthesis. With its high strength and low coefficient of linear expansion, it can withstand 70℃ working temperature, so its service life is more than 50 years.

Benefits of Anti-Bacterial PPR Pipe

Excellent durability

Anti-bacterial PPR pipes are known for their exceptional durability. They are resistant to corrosion, chemical deterioration, and scale formation. This makes them suitable for both hot and cold water systems, as well as for the transportation of various chemicals. Anti-bacterial PPR pipes have a long lifespan, which reduces maintenance and replacement costs over time.

High temperature resistance

One of the major advantages of anti-bacterial PPR pipes is their ability to withstand high temperatures. They can handle temperatures up to 95°C, making them ideal for hot water supply systems. The heat resistance of anti-bacterial PPR pipes ensures safe and reliable distribution of hot water without the risk of deformation or damage.

Low thermal conductivity:

Anti-bacterial PPR pipes have a low thermal conductivity, meaning they are excellent at retaining heat. This property helps maintain the temperature of the transported fluids, resulting in energy savings and increased efficiency. anti-bacterial PPR pipes also prevent heat loss, ensuring consistent water temperature throughout the entire plumbing system.

Easy installation and maintenance

Anti-bacterial PPR pipes are lightweight and flexible, making them easy to handle and install. They can be joined using a simple fusion welding technique, eliminating the need for additional connectors or fittings. The smooth inner surface of anti-bacterial PPR pipes reduces friction, preventing the accumulation of deposits and ensuring a continuous flow of water. Their low maintenance requirements make them cost-effective and hassle-free.

Wide range of applications

The versatility of anti-bacterial PPR pipes allows for a wide range of applications. They are commonly used in residential buildings, commercial complexes, and industrial facilities for plumbing, heating, and cooling systems. Anti-Bacterial PPR Pipes are also widely used in agricultural irrigation, as they can withstand harsh weather conditions and resist the growth of algae or bacteria.

Anti-Bacterial PPR Pipe is constructed by polypropylene for the main body and ag ion antibacterial master batches inner layer. Using two layer co-extrude technology, the outer layer is the normal, antibacterial layer with Ag Ion. Ag ion antibacterial master batches are added to the inner layer. They release a little Ag ion which inhibits the ecto-enzyme'activeness and bacteria's reproduction and come to the effect of killing bacteria.

Low thermal conductivity

The thermal conductivity of PPR is very low, meaning temperature cannot easily be conducted from the outside environment to the liquid in the pipe, and vice versa. This factor reduces heat loss or gain during the transferring of hot or cold fluids respectively, resulting in energy efficient systems and lower insulation costs for PPR piping.

Long service life & durability

PPR piping systems can remain functional for over 50 years, at a wide range of fluid and environmental operating temperatures. Moreover,

Anti-Bacterial PPR Pipe exhibits excellent durability in both hot and cold water systems. Firstly, it can endure the temperature and pressure strain of hot water systems.

At the same time Anti-Bacterial PPR Pipe is able to structurally withstand impacts even in cold weather installations without any risk of cracking or breaking, unlike other common types of plastic piping.

Efficient inner surface

The inner surface of Anti-Bacterial PPR Pipe is very smooth and boasts a very low friction coefficient, compared to traditional types of piping. This results in a reduction of pressure losses during fluid transport and distribution, further contributing to the energy efficiency of PPR piping systems. Moreover, unlike metal pipes PPR does not flake or scale, making them safer to use.

Chemical & mechanical endurance

Compared to traditional plastic piping systems, PPR offers very high resistance against abrasion by hard particles. This is especially important in cases of well water or industrial applications, where the transferred liquids may contain abrasive particles.

Unlike traditional metal piping, PPR is inert to most electrolytes and chemicals, over a wide range of temperatures. This electrolytic and chemical inertness makes PPR piping safe to use in cases of high water salinity (eg. in pool applications that use sea water) or even highly corrosive chemicals (eg. in industrial applications).

Ecological & economic efficiency

Due to the low weight of Anti-Bacterial PPR Pipe, their transport, handling, and installation doesn't require high amounts of energy consumption or manual labor. At the same time they are very easy to cut, join, and work with, making them even more economically sustainable.

Moreover, joining Anti-Bacterial PPR Pipe and fittings is performed solely through heat and doesn't require any additional chemicals or materials. All of these factors contribute to PPRs low environmental impact and usage cost.

PPR pipe applications

The durability, economical, and ecological advantages of PPR has resulted in it being used for an increasing number of diverse applications in recent years.

Water supply systems

Anti-bacterial PPR pipe fittings are commonly used in water supply systems for both cold and hot water. Their ability to withstand high temperatures without breaking or cracking makes them an ideal choice for transporting water.

Sewage systems

Anti-bacterial PPR pipe fittings are suitable for discharging chemical fluids, including industrial waste, due to their resistance to strong chemicals and alkaline solutions.

Heating systems

Anti-bacterial PPR pipes are perfect for building heating systems, such as radiant and wall heating systems. They can withstand various surfaces and conditions, making them a reliable option for all heating needs.

Air conditioning systems

Anti-bacterial PPR pipe fittings are also used in air conditioning pipe systems, ensuring the efficient transfer of fluids throughout the system.

Irrigation systems

Anti-bacterial PPR pipes can be used for irrigation purposes, providing a reliable and durable solution for transporting water to agricultural fields or gardens.

Gas transmission

Anti-bacterial PPR pipe fittings can be used for gas transmission in certain applications, as they have good resistance to chemicals and can ensure the safe transportation of gases.

Fire suppression systems

Anti-bacterial PPR pipes meet UL standards for fire suppression systems, making them suitable for carrying gases or liquids from tanks to nozzles or sprinklers in buildings.

Other applications

Anti-bacterial PPR pipe fittings are also used in various industries that require non-metallic piping components, such as dairy farms, commercial kitchens, commercial complexes, and hobbyist projects.

How To Join Anti-Bacterial PPR Pipe

Joining anti-bacterial PPR pipes is a straightforward process that requires careful attention to ensure a proper connection. Here is a step-by-step guide for joining anti-bacterial PPR pipes:

Prepare the pipes: Cut the anti-bacterial PPR pipes to the desired length using a pipe cutter or saw. Ensure that the ends are clean and free from debris.

Prepare the fittings: Clean the inside of the PPR fittings using a cleaning brush or sandpaper to remove any dirt or debris. Ensure that the fittings are dry before proceeding.

Heat the pipes and fittings: Use a PPR welding machine to heat both the pipes and fittings. The machine should be set to the appropriate temperature for the specific PPR material being used.

Insert the pipes: Insert the heated pipes into the corresponding fittings while the material is still hot. Apply slight pressure to ensure a tight fit.

Hold and cool: Hold the pipes and fittings together for a few seconds to allow them to cool and solidify. This will ensure a strong and secure connection.

Repeat the process: Repeat the process for each joint, ensuring that all connections are properly heated and secured.

Remember to follow the manufacturer's instructions and guidelines for the specific anti-bacterial PPR pipes and fittings being used. It is essential to use the correct temperature and heating time to avoid damaging the pipes or fittings.

How to Choose Anti-Bacterial PPR Pipe

Determine the flow rate

Assess the flow rate required for your specific application. This involves understanding the volume of water or fluid that needs to be transported through the pipe over a given period. Higher flow rates generally require larger diameter pipes.

Consider the application

The nature of the application greatly influences the pipe size. For instance, supply lines for fixtures like sinks and toilets may require smaller diameters, whereas main supply lines or industrial applications might need larger diameters for greater water volume.

Pressure requirements

Evaluate the pressure requirements of the system. Higher pressure systems may need pipes with thicker walls to withstand the pressure, especially if the diameter is large.

Calculate the velocity of water

Ensure the velocity of water in the pipe is within an acceptable range. Too high velocity can lead to noise and wear, while too low velocity can cause sedimentation in the pipes.

Check local codes and standards

Refer to local building codes and plumbing standards, as they often specify the minimum and maximum sizes for different applications.

Consult with experts

For complex systems, consulting with a plumbing expert or engineer is advisable. They can perform detailed calculations considering all variables, including flow rate, pressure, and intended use, to recommend the right pipe size.

Professional installation

One of the most critical aspects of preventing anti-bacterial PPR pipe issues is ensuring proper installation. Hiring a qualified and experienced plumber is essential to ensure that the pipes are correctly fitted, connected, and aligned. Amateur installation can lead to leaks, weak joints, and other problems down the line.

Use high-quality anti-bacterial PPR pipes

Always choose high-quality anti-bacterial PPR pipes and fittings from reputable manufacturers. Inferior quality materials may be prone to premature wear, cracks, or deformation. Investing in quality pipes upfront can save you from costly repairs and replacements later on.

Regular inspections

Regularly inspect your PPR plumbing system for any signs of leaks, cracks, or damage. Detecting problems at an early stage can help prevent them from escalating or deteriorating further. Look for wet spots, discoloration, or unusual odors around pipes and fittings.

Temperature and pressure control

Anti-bacterial PPR pipes are sensitive to high temperatures and pressure fluctuations. Ensure that your hot water system is correctly regulated to avoid overheating the pipes, which can lead to deformations and leaks. Also, consider installing pressure relief valves to protect the pipes from excessive pressure.

Avoid DIY modifications

Avoid making DIY modifications to your PPR plumbing system unless you have the necessary expertise. Incorrect alterations can weaken the structure and cause leaks or failures.

Proper insulation

In colder climates, insulate your anti-bacterial PPR pipes to prevent freezing. Frozen pipes can expand and crack, leading to leaks when they thaw. Proper insulation can help maintain a consistent temperature in the pipes.

Avoid chemical contamination

Exercise caution when disposing of substances in your drains. Harsh chemicals and corrosive substances can damage anti-bacterial PPR pipes over time. Opt for environmentally friendly cleaning products and avoid disposing of chemicals directly into your plumbing system.

Periodic maintenance

Consider scheduling routine maintenance checks by a professional plumber. They can identify and address potential issues before they become major problems. Maintenance may include tightening connections, inspecting seals, and ensuring proper water flow.

Use proper tools and fittings

When working with anti-bacterial PPR pipes, make sure to use the correct tools and fittings recommended by the manufacturer. Using the wrong tools or mismatched components can result in weak joints and leaks.

Protect anti-bacterial PPR pipes from uv exposure

Anti-bacterial PPR pipes are sensitive to ultraviolet (UV) light. If your plumbing system is exposed to sunlight, use UV-resistant covers or paint to shield the pipes from UV damage.

Regular cleaning

Periodically clean your anti-bacterial PPR pipes to remove sediment, mineral deposits, and other buildup that can affect water flow and quality. Flushing the system with clean water can help maintain its efficiency.

Certifications

Ningbo Amico Plastic Industry Inc. located in Ningbo China, is a stock-holding enterprise, which specialized in producing pipes and fittings. With annual productivity over 10000 tons, Ningbo Amico Plastic Industry Inc. mainly produce plastic aluminum pipe, PP-R pipe, PE-RT pipe, HDPE pipe, PE-RT heating pipe series, brass adapter etc.

FAQ

Hot Tags: anti-bacterial ppr pipe, China anti-bacterial ppr pipe manufacturers, suppliers, factory, Garden hose with brass fittings, poly drain, brass connector pipe, Brass 3 way tap connector, Brass expansion fittings, Decorative Brass Fittings

Send Inquiry